Matahio New Zealand Production Optimisation

The “every barrel” aspect of Matahio approach to Operations Excellence has delivered impressive results in New Zealand.

The “every barrel” aspect of Matahio approach to Operations Excellence has delivered impressive results in New Zealand.

The “every barrel” aspect of Matahio approach to Operations Excellence has delivered impressive results in New Zealand.

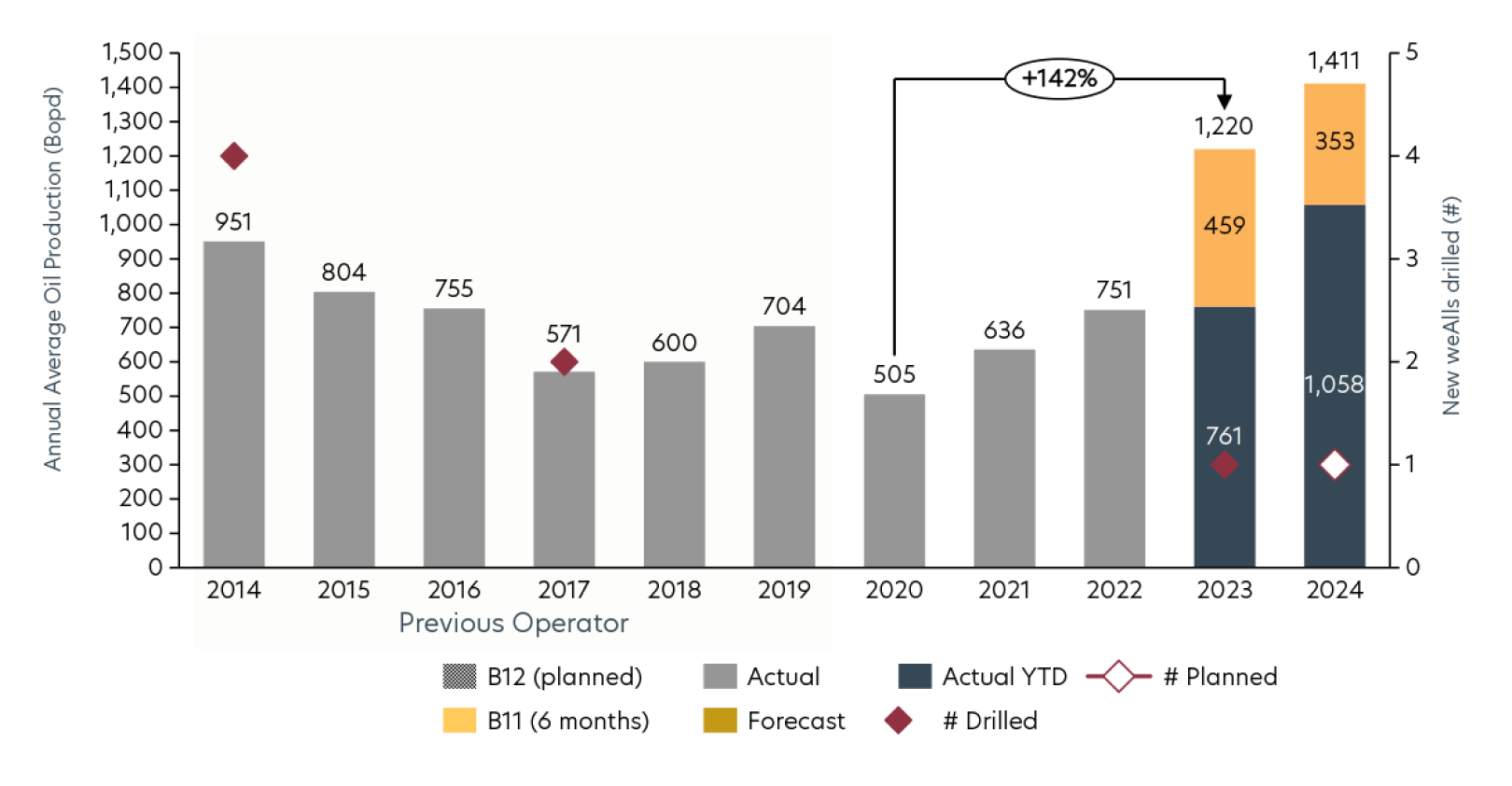

Production across the Cheal Field, onshore Taranaki, New Zealand had been declining for several years prior to Matahio's team assuming Operatorship in late 2019. However, with a rigorous “every barrel, every dollar” mindset the combined in-country and HQ Development Team were confident this could be turned around.

Despite the additional challenges of COVID and an oil price crash, the teams have succeeded in returning the field to production levels last seen in 2016, without the need for infill drilling. Here's how it's been achieved.

The Matahio team have built a strong track record in maintaining and, ultimately improving, production performance of otherwise declining fields. To make improvements at Cheal the team needed to tackle issues across the entire production chain: the reservoir, the wells and the facilities.

Employing best-practice via an innovative Cloud-based production management tool developed by in-house engineers in collaboration with a leading contractor.

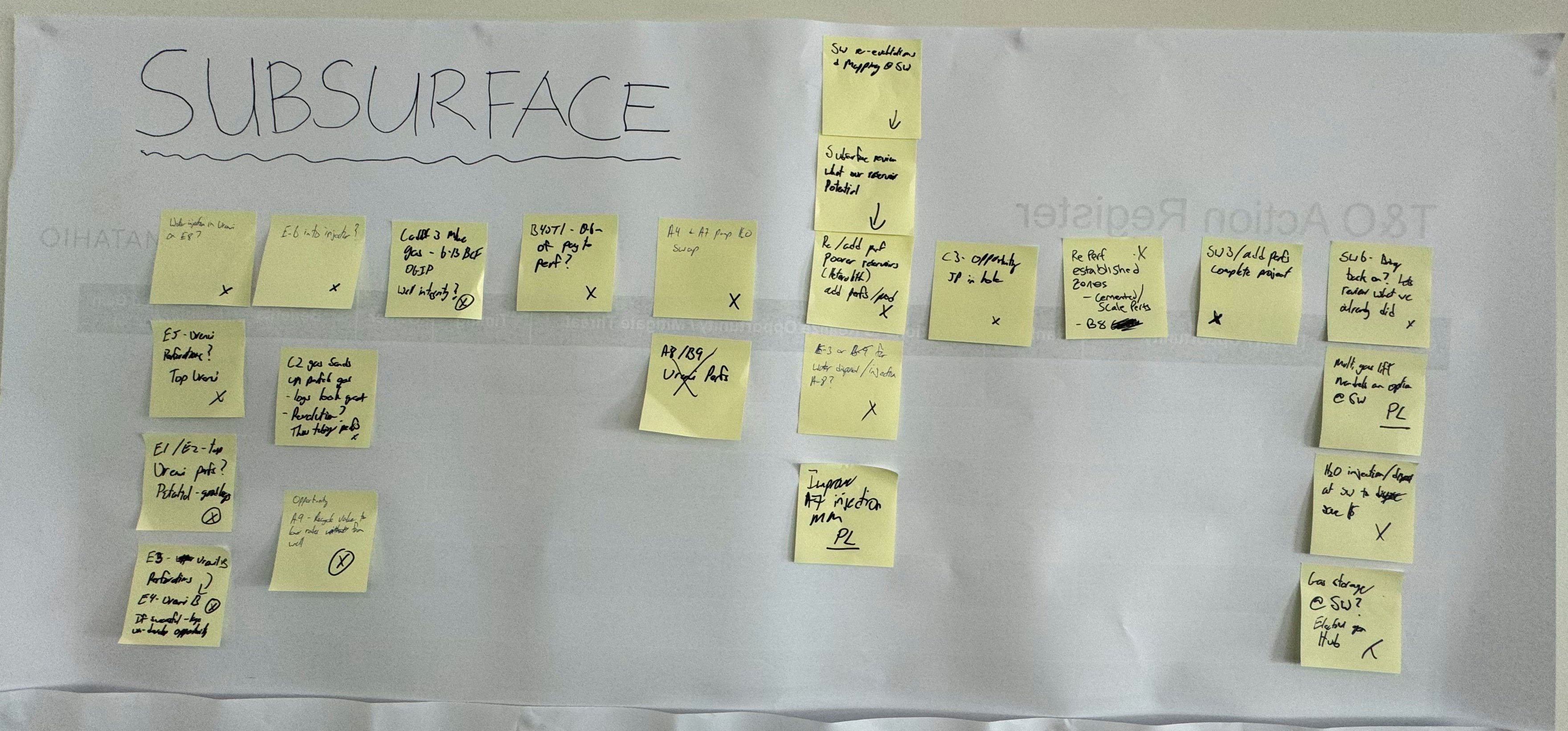

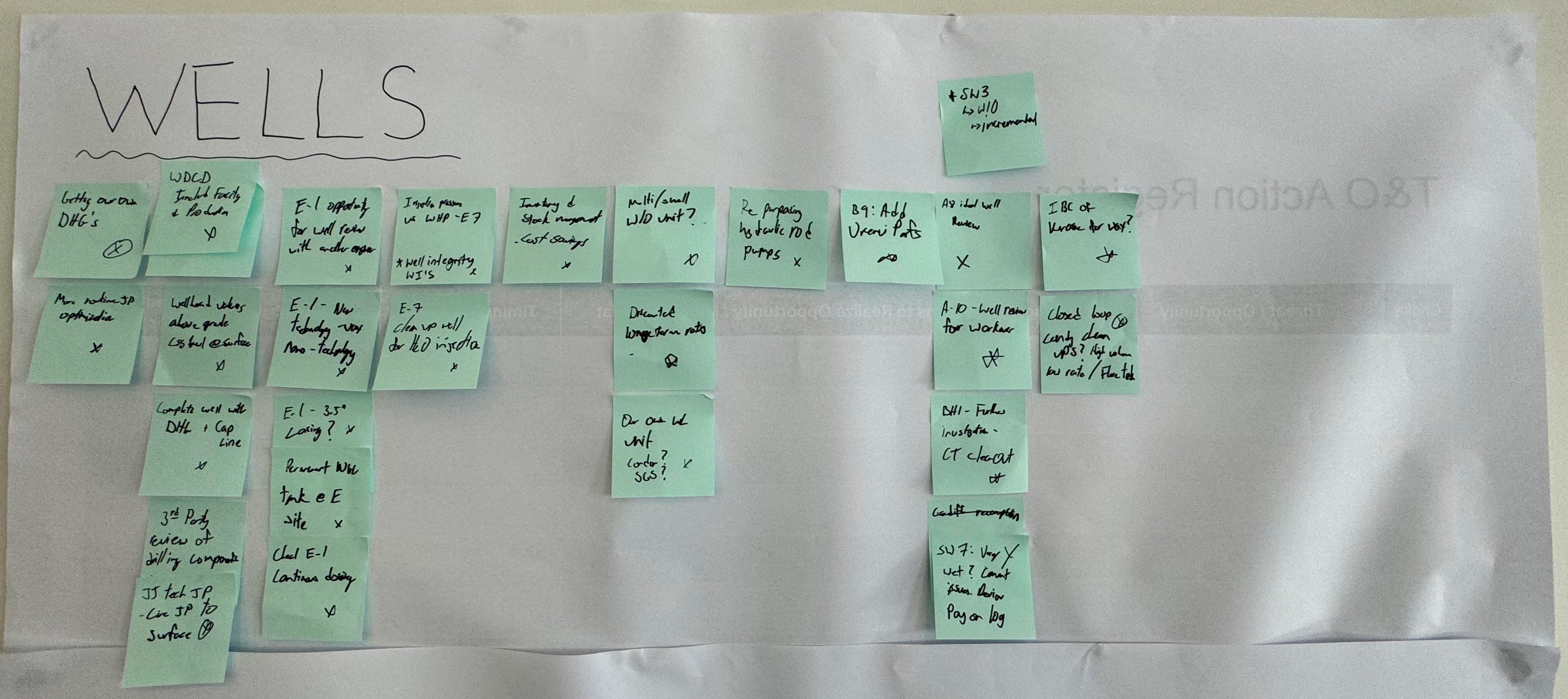

Uncovering opportunities abound in a complex field such as Cheal, if you know how to look. The Matahio team runs regular multi-disciplinary Produce the Limit workshops to surface ideas and scope their execution.

Cheal availability 97% by 2023. Compared to 2020, production losses reduced by 77% and downtime from key operational parameters also greatly reduced.

Making the most of the existing well-stock by enhancing artificial lift by replacing constrained rod pumps with new concentric jet pumps to improve reliability and access further upside production.

Below is our production performance from the Cheal ABC field, showing the resultant improvement in our production performance:

All good optimisation starts with doing the basics right. This requires a rigorous approach to production management where the Technical Potential of the entire production system is well understood and every “Boe” is accounted for.

Matahio ensures efficient consolidation of all production data by utilising TITAN, a powerful production management tool developed jointly by in-house engineers and THREE60 Energy. The key features of this world-leading tool are:

Complete database of well history.

Full production data including oil, gas, water (produced & injection), pressure, temperature and chemical treatments.

Loss module to track under-performance against Matahio defined categories.

Reporting and data extraction tools to allow interrogation of data at Group, Asset, Field and well level.

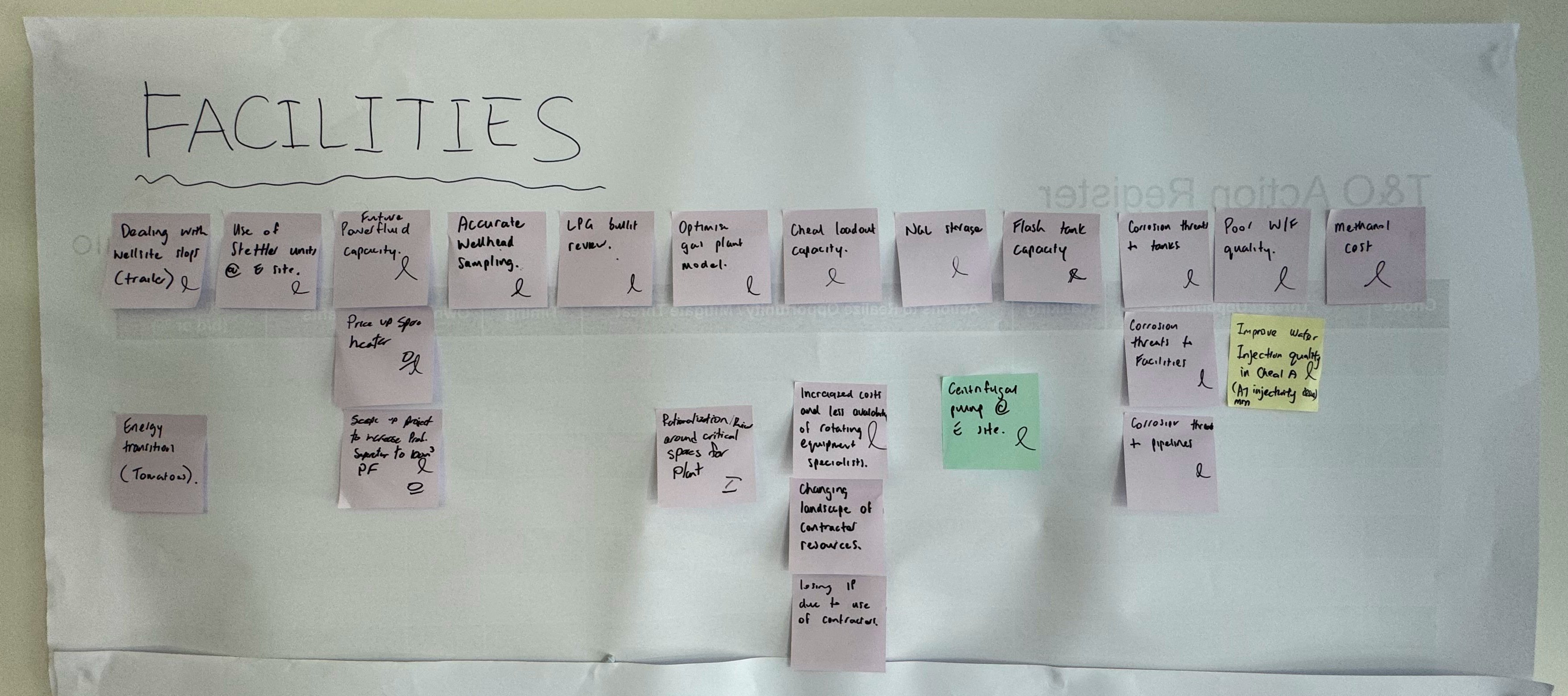

Matahio run Produce the Limit (PtL) workshops for all its Operated assets, bringing together members of the Corporate Development Team, in-country operations staff and contracting partners. Step-by-step every production “choke” is assessed, and any constraints are identified. This stage of the exercise often yields a number of opportunities to de-bottleneck the production system.

The Produce the Limit process normally takes 3-4 days. Through this structure, Matahio's experienced team have identified further opportunities such as:

Adding new perforations to access bypassed oil.

Right-sizing equipment and settings for the current phase of the field's life-cycle.

Reducing waste (recycling gas, on-site cleaning and oil recovery, etc).

Improved testing accuracy.

Compressing well-head micro-annular gas to further enhance drawdown and improve production.

Not every idea either makes it all the way to execution or indeed yields exactly the forecast result. However, at Matahio we believe you learn from your failures, so the technical and operational teams continue to push the limit.

The Cheal asset has historically had poor up-time due to vulnerabilities in the power supply. Power failures not only rendered portions of the plant and artificial lift inoperable for the duration of the outage, but also exposed wells to waxing. Consequently, wells were often either difficult to re-start or condemned to workovers, sometimes shut-in for months awaiting a suitable rig.

Matahio has significantly improved availability by reducing downtime of key operations. Compared to 2020 levels, rod pump failure is down 80% and plant shutdowns are down 93%, resulting in Cheal availability of 97% in 2023. This has been achieved by:

Investing in a state-of-the-art switchgear to allow seamless change-over from grid to site generated power without causing the plant to trip in event of an external power failure.

Installing on-site power generation ‐ enabling the ability to export power when gas prices are low.

Rerouting waste gas to keep one genset running 24/7.

All wells at Cheal require artificial lift to maintain production. Numerous rod pumps were installed by the previous Operator. These proved unreliable and upon close inspection of the wells' potential also represented a constraint.

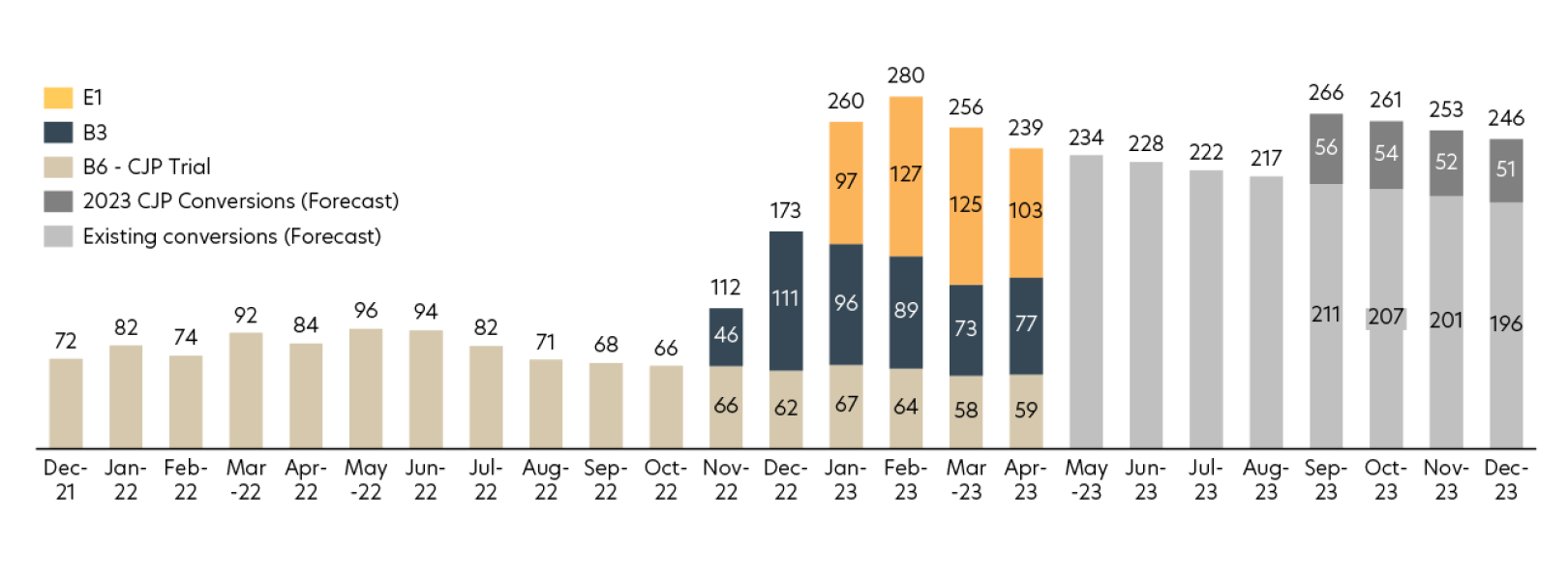

Over recent years Matahio has systematically replaced these rod pumps with Concentric Jet Pumps (CJPs), which, as well as improving reliability, incorporate “velocity strings” to optimise reservoir draw-down and improve production.

Matahio's were the first to introduce CJPs to New Zealand. As is prudent with the adoption of any new technology Matahio initially carried out a trial from late 2021, with further workovers adding incremental production from 2022 onwards. To date Matahio have completed six jet pump conversions, which have improved production across the field by nearly 20%.